Three Things To Know Before Considering Automated Parking

February 8, 2023Although there are infinite options and a wide selection of parking solutions in the market, not all of them are created equal. The available options range from simple mechanical (dependent) lifts or stackers to sophisticated automated (independent) systems up to 260’ high.

The main difference between mechanical and automated systems is their “dependency”. Dependent mechanical systems require a driver to manually park and retrieve the vehicle from the lift and also to manually operate the platforms that perform the lifting and descending movements.

On the other hand, independent automated systems do not require a driver to park or retrieve the vehicle nor to operate the platforms. The system will perform all these operations without drivers or attendants.

The images below exemplify the very relevant difference between dependent and independent systems.

The system on Fig. A is a mid volume configuration using mechanical stackers; and the system on Fig. B is also a mid volume configuration using automated systems. Both systems can be configured to have similar footprints and height and to hold the exact same amount of cars. In other words, they are comparable in space saving capabilities, volume and parking capacity; but mechanical systems are less expensive, so, no brainer right? WRONG.

Let’s say a driver comes to retrieve a vehicle that is located on the top (fourth) level of the mechanical stacker on Fig A. An attendant will literally have to:

- Get on the car on the ground level,

- drive it out of the system,

- temporarily park it on the drive aisle,

- exit the vehicle and approach the system,

- manually lower the second floor platform,

- get on the vehicle and remove it from the platform,

- park it on the drive aisle,

- exit the car and approach the system,

- manually lower the third platform,

- get on the vehicle and park it on the drive aisle,

- Exit the vehicle and approach the system

- Lower the top platform, remove the vehicle and give it to the driver

Then, the attendant will need to:

- Park one of the vehicles he left waiting on the drive aisle,

- exit the vehicle, approach the system and lift the platform,

- get on the second vehicle left waiting on the drive aisle,

- park on the platform, exit the vehicle and lift the platform

- park the third vehicle left on the drive aisle, exit the vehicle and lift the platform…

Yes, we are exhausted too.

How long do you think the retrieval operation above will take? Exactly… that is why mechanical systems are seldom (if at all) recommended for parking operations. The natural use of mechanical stackers is storage (like car dealerships).

Now, let’s look at the performance of the Automated System in the same situation.

- The driver comes, parks the car on the ground floor and leaves.

- The driver comes back and calls the vehicle,

- The system brings the vehicle to the ground floor,

- the driver gets on the vehicle and leaves.

The secret? Automated Systems move cars, without drivers or attendants, to the upper storage levels until said cars need to be retrieved. Then, the system brings the car back to the ground floor when called, and the driver enters and leaves. DONE.

See the difference? The first solution will create absolute chaos on a parking operation if, say, a few drivers were to come at the same time. The second parking solution however, will take a few minutes. So, dependency is key when deciding which solution is right for your project as this specific condition will determine the “throughput” of the parking operation.

Throughput refers to the number of cars you can move in a given period of time. Throughput is the base of a successful (or failed) parking operation, so a responsible automated parking integrator will pay special attention to this variable when assessing which solution best adapts to the specific characteristics of each project.

Designing an appropriate throughput will ensure flow and redundancy even during the busiest times.

That said, lets dive into the most popular parking systems in the market.

Mechanical (dependent) 2-level Lift/Stacker

Mechanical (dependent) 3 to 4-level Stacker

Pit Four Post

Rotary Parking System

Bidirectional (puzzle) Parking System

Tower Parking System

Rack & Rail

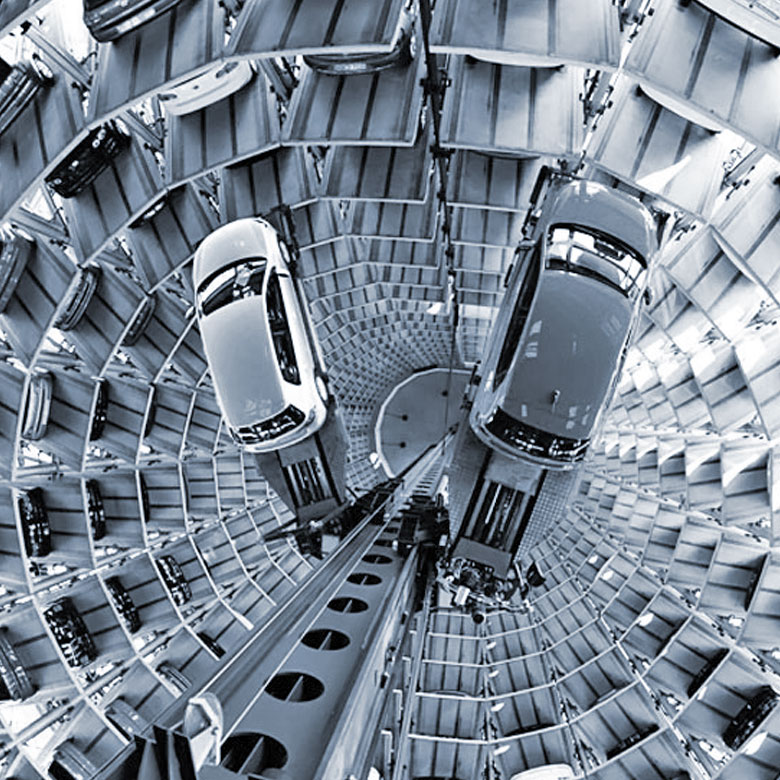

Silo Parking System

AGV (Automated Guided Vehicle)

View

Why invest in Automated Parking?

Ready to take your parking to the next level?

Contact us to learn more about our specialized services and how they can benefit you.

All non-hybrid parking systems are stand alone and may be eveloped according to architectural preferences or to integrate with the surrounding architectural fabric. When systems are placed inside a building they may not require envelope, therefore reducing building costs.

When systems are exposed, appropriate envelopes need to be discussed and designed. Some systems required just to be roofed and some require full enclosure. Appropriate protection will depend on the type of system and the weather conditions particular to the location where the system will be installed.

Automated Parking has become a more sustainable, space efficient and cost-effective solution to the parking hurdle. The upside of this technology is that it offers unparalleled flexibility when compared to the alternatives; the downside however, is that is very difficult to standardize.

Automated Parking Solutions are “custom-designed” and therefore, there is no straight or “cookie cutter” answer. System selection and configuration respond to an array of variables; and integration into any particular operation requires the expert to evaluate all these variables to determine wich option or solution is the best possible fit.